SPH2 High frequency pipe welder

700KHZ High frequency pipe weldermore >

400KHZ Pipe welding mmachinemore >

SPH2 High frequency pipe welderintroduction

SPH2 series pipe High frequency welder, Output frequency 200~700KHZ,output power 20~300KW, is specially designed for pipe high frequency welding application, such as steel pipe high frequency welding, stainless steel pipe high frequency welding and aluminium pipe high frequency welding. By using our latest control technologies, SPH machines realize varieties of advantages such as excellent output stability , small size, high heating efficiency, low energy loss and high reliability.

(1) Frequency 200—500KHZ, SPH2 series products

This series products are used for steel pipe and stainless steel pipe high frequency welding. Main models include: SPH2-20、SPH2-30、SPH2-40、SPH2-60、SPH2-100、SPH2-150、SPH2-200 and SPH2-300

(2) Frequency 400--700KHZ, SPH700K2 series products

This series products are used for aluminium pipe high frequency welding;Main products include: SPH700K2-20、SPH700K2-30、SPH700K2-40 and SPH700K2-60

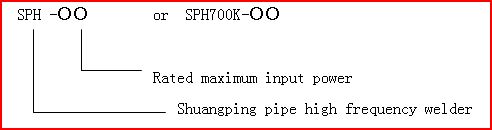

1. SPH2 model definition

(1) Series oscillating circuit is adopted in SPH2 machines, Inverting High frequency power is output to transformer which is in series with oscillating caps and then output to induction heating coil.

(2) In SPH2 products, High frequency regulate technology is used to control the output power instead of traditional SCR regulate technology, High speed regulate and high stable output is achieved to maintain a smooth welding joint.

(3) MOSFET is used for SPH2 inverting switching components and large power oscillating caps are used , together with our unique soft switching inverting technology, High stable oscillating output is achieved to stable the pipe welding procedure for good welding quality.

(4) High efficiency and low energy loss: From input to output, soft switching technology is adopted inside SPH2 machines to realize high heating efficiency, low energy loss and high power factor through the whole power ranges. Compared with traditional vacuum tube high frequency pipe welder, 30~40% energy loss can be avoided.

(5) Safety: there is no high voltage of up to 10KV inside SPH products to avoid radiation, circuit disturbing, spark, disge and other phenomenon.

(6) Small size and one body, save space a lot. No need for step-down transformer, no need for big inductance which is essential for SCR equipment, Small size of SPH2 products makes easy for installation, maintenance, transportation and trial.

(7) Inside SPH2 machines, varieties of protection are used such as over current protection, phase fail protection, over temperature protection, over voltage protection, short circuit protection, phase fail protection to achieve high reliability of the machine and to ease the repair and maintenance.

(8) Frequency, current, voltage and power is displayed in SPH2 machines to make the working status clear and to ease the designing of coil.

Location:

Location:

Medium frequency induction heating machine

Medium frequency induction heating machine

Company address

Company address